The use of fly ash as the primary component in Boral TruExterior products is about more than sustainability: Fly ash is what helps make TruExterior a high-performing, dimensionally stable, long-lasting product for a range of exterior applications.

Scientists and researchers in Boral’s Innovation Factory, which takes its physical form at a laboratory in San Antonio called the Discovery Center, spent years developing Boral TruExterior, including seeking the ideal raw material that would provide the look of wood with properties superior to not only natural products but what was available in manmade products.

The answer lay in fly ash, a byproduct of coal-combustion power generation that typically is sent to the landfill but in recent years has been discovered as a beneficial material for products including brick and concrete. Our scientists discovered a number of properties that contributed to fly ash being the ideal raw material.

Ideal Attributes

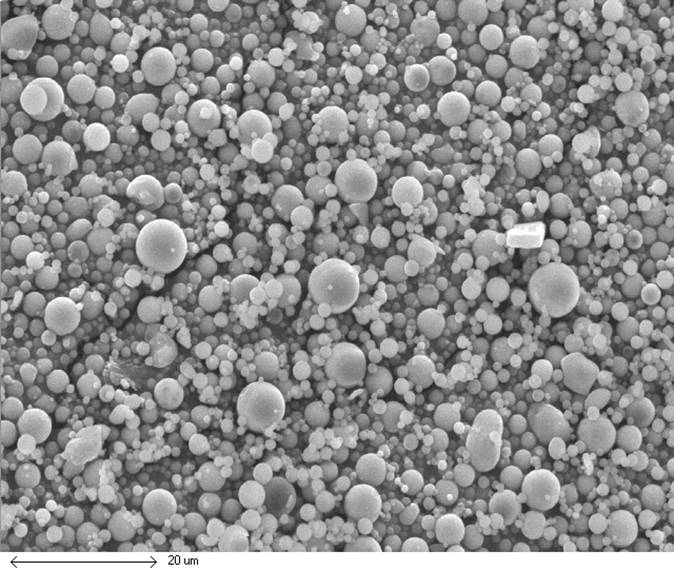

First, fly ash offers an ideal shape and size for balancing inexpensive inorganic material with expensive polymer adhesives. When manufacturers create the base material for their product, which for siding is a mixture that flows into molds or is extruded, they typically combine several ingredients, one or more of which is a glue or resin to hold everything together and fill in the “gaps” between the ingredient particles. In the case of TruExterior, fly ash is bound with a polymer. Ideally, formulations use as much inorganic material as possible, and therefore less polymer filling in the gaps, to keep costs down. Fly ash is ideal because it is spherically shaped and comes in several particle sizes. The spherical shape, rare in natural materials available in such abundance, exposes less surface areas for a given volume to be covered by a polymer. And with many different particle sizes, smaller fly ash particles will fill in the gaps between larger particles, much like if you poured sand into a jar of pebbles. Both of these properties mean less polymer is needed to fill the space and coat the particles.

The spherical shape also helps the material flow more easily.

From a performance standpoint, fly ash material is inert and inorganic. And because it is stable, it doesn’t react significantly with the environment, which is what helps TruExterior Siding & Trim remain dimensionally stable amid changes in moisture and temperature.

The scientists in the Innovation Factory were able to harness these discoveries and create a completely new category of building products—poly-ash. The resulting siding and trim products in the TruExterior family offer the look and workability of wood, while offering exceptional durability; resistance to cracking, rotting, splitting, and insects; and a high level of dimensional stability during periods of moisture and temperature change.

Finally, the use of fly ash does offer an important sustainability story: Seventy percent of TruExterior products use the recycled material, which would otherwise be bound for the landfill.

To learn more about the benefits of TruExterior Siding & Trim, click here.