Not all vinyl siding is created equal. Depending on material, technology, manufacturing processes, and other factors, vinyl siding comes in a range options and price points that vary in both performance and aesthetics. Among those options is insulated vinyl siding, which, just as it sounds, is vinyl siding with a foam backing that can help enhance both the appearance and the thermal insulation value of the home.

What’s Unique About Insulated Vinyl Siding?

The insulation board on the back of CraneBoard® Solid Core Siding® from Westlake Royal Building Products™ is just 1-1/8-inch inch thick, but it packs quite a benefit punch.

High-End Aesthetics

You can notice the difference from the curb: Because the insulation backing provides for a more robust, stiff panel, CraneBoard comes in wide, architecturally correct 6-inch and 7-inch panels for a truly authentic cedar look and in 12-foot and 16-foot lengths for fewer seams. The rigid panel helps straighten walls for a clean, smooth finished appearance.

Along with the wider profiles, CraneBoard also is available in Quad 4.5-inch Dutchlap and Board & Batten styles to meet any design aesthetic.

Improved Thermal Performance

Insulated vinyl siding wraps the home’s exterior in a layer of continuous insulation, helping to reduce what’s called “thermal bridging.” This phenomenon occurs when heat and energy escape the house through the pathway of the house framing, which, unlike a wall cavity, is not insulated. By collectively covering those framing studs with foam insulation, insulated vinyl siding helps dramatically reduce heat loss.

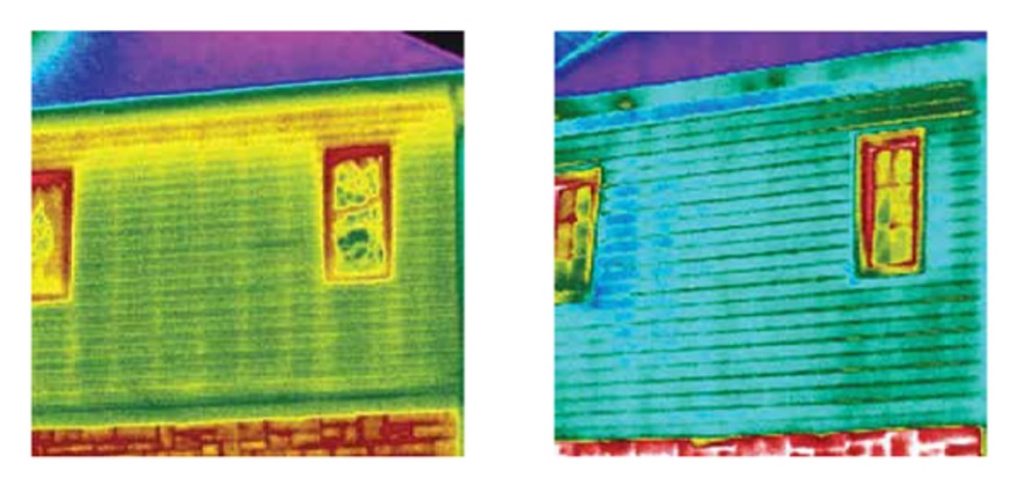

You can see how this works in this side-by-side comparison using a thermal imaging camera. On the left is a house without insulated vinyl siding. The yellow area shows how heat transfers through the studs. On the right is the same house with CraneBoard siding; CraneBoard, shown in blue, cuts down on the energy lost through the studs of the home’s walls.

As a result, CraneBoard Solid Core Siding offers significantly more insulating power than fiber cement, wood, engineered wood, or brick.

Noise Reduction

The foam insulation backing on CraneBoard also helps reduce the transmission of external noise, contributing to a quieter interior.

Moisture Management

CraneBoard Solid Core Siding is the only insulated siding with the Smart Track™ system with moisture management ridges, which helps water that may be behind the siding (due to wind-driven rain or through vapor coming through the wall assembly) to escape.

CraneBoard Insulated Vinyl Siding Offers Color That Lasts

Along with the added value the insulation brings, CraneBoard Solid Core Siding offers a range of additional benefits that contribute to longevity in form and function.

Unlike wood, engineered wood, and fiber cement, CraneBoard siding doesn’t require periodic caulking or repainting. It features Chromatix® technology color protection to help

effortlessly maintain the original look. In fact, the use of Chromatix technology enables Westlake Royal to warranty fade to as low as 4 Hunter Units (a common measure of color difference). (Read more about this here.)

So whether your customers are seeking the richness of Lighthouse Red, the brilliant blue of Indigo, or the cozy appeal of Greystone, they can count on color the lasts, siding that is easy to maintain, curb appeal the endures—and the added power of insulation.

Learn more about CraneBoard here.