For nearly 30 years, North Iowa Area Community College’s (NIACC) Building Trades Diploma Program has been jumpstarting students into a career in construction. Westlake Royal Building Products is helping boost their efforts with a Tapco Tools brake donation to train the students in the craft of custom exterior trim.

Designed for students interested in a career in residential, commercial, or industrial construction, NIACC’s one-year Building Trades Diploma Program combines classroom instruction (to teach safety, blueprint reading, and craft work processes), manipulative lab projects (a mock jobsite setting where students learn at their own pace), and eight-week mentored jobsite internships. “NIACC Building Trades students will have opportunities for nationally recognized certifications including NCCER, OSHA, and other optional industry-related certifications,” the school explains. “The Building Trades Lab is a state-of-the-art facility where students learn in an individualized, competency-based setting, mastering skills by constructing manipulative projects.”

Though most of the students are just starting their careers—recent high school grads or high school students earning dual credit—the school has participants of all ages. The Diploma Program spans 37 semester hours across three semesters. A Certificate Program (two semesters) and a Fundamentals of Construction (45 hours) also are available, among other related courses.

Part of the program’s current hands-on training is work on a local Habitat for Humanity house. A few years ago, the students participated in an episode of Extreme Makeover Home Edition.

Gregg Helmich, a building trades instructor who leads the NIACC program, says that sometimes graduates go directly into the construction workforce, often by being hired through their internships. For others, it’s a springboard to other programs or more intensive training opportunities. Either way, he notes, the diploma typically leads to a higher starting wage, which helps them stick with it.

Tapco Tools Brake Donation Will Have Immediate Impact

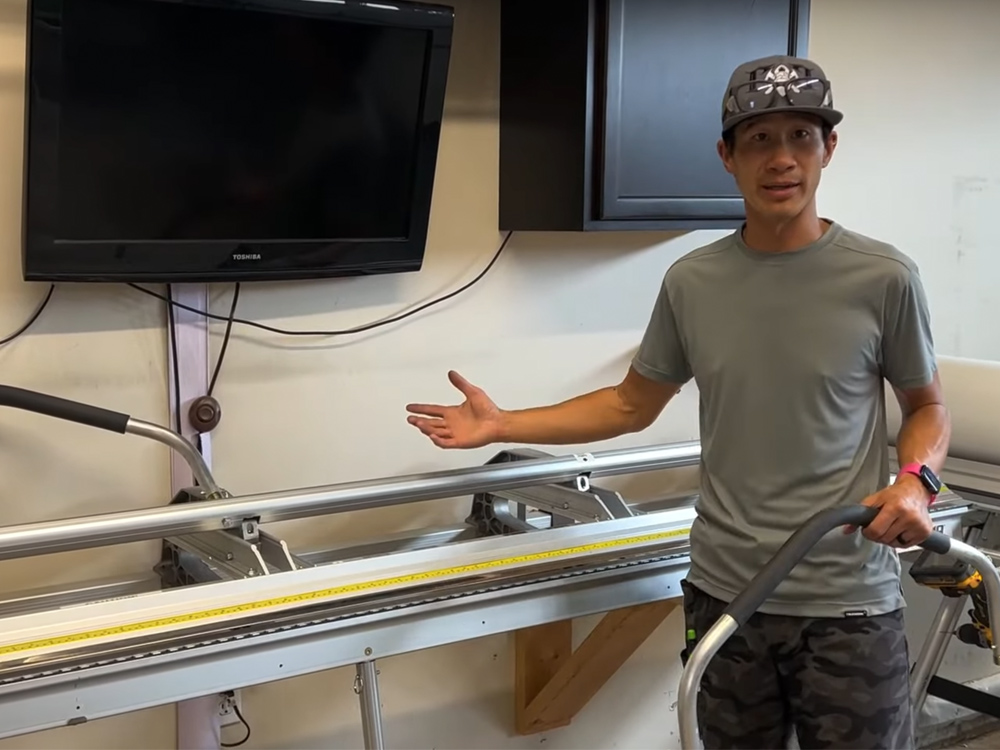

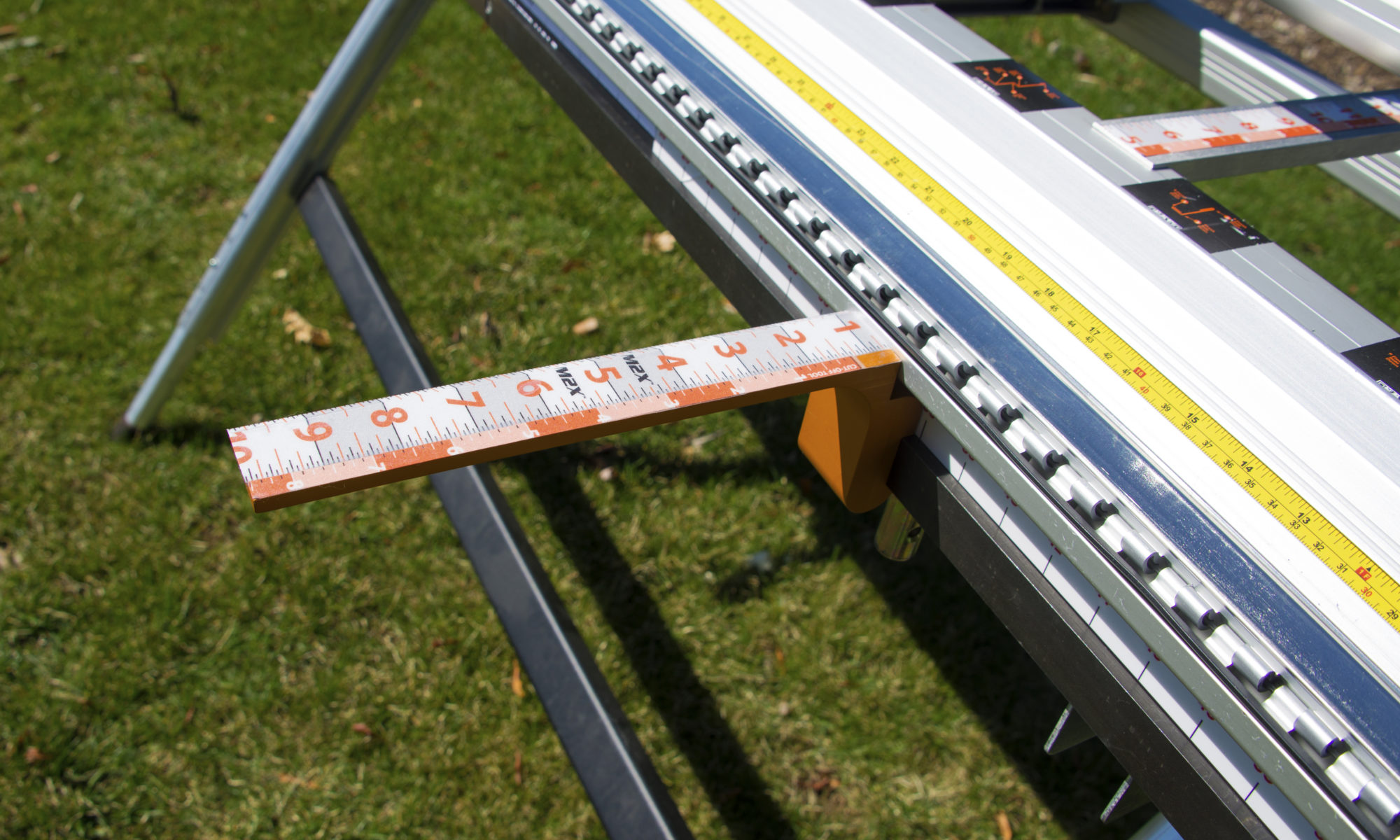

During the 2023 International Builders’ Show, Westlake Royal Building Products handed off the Tapco Tools brake donation, a PRO 14 brake, to Helmich for the NIACC Building Trades Diploma Program. The PRO 14 allows for easy, efficient crafting of high-quality custom trim pieces for siding and roofing applications, including soffit, fascia, brickmold, sill trim, window casing, chimney flashing, and more.

Tapco Tools also donated a Snap Stand; a Side-Winder, which secures the coil to the brake; a PRO Cut-Off for safer, single-pass cutting; and a Brake Buddy, which allows the user to elevate trim work with more style and originality.

“The sky’s the limit to be able to use this in different ways,” Helmich says. “Students love to get hands-on—a video can only do so much.”

Along with fundamentals of custom bending, Helmich says the brake connects students with building science principles. “We’re embracing the building science community … often it asks for flashings that aren’t available in stores, so using the brake is great to create kickout flashing and other things to keep water away,” he explains.

For recruiting purposes, the brakes and other innovative tools come in handy for design/build events at local high schools, where students can see how a simple roll of coil becomes an intricate piece of trim.

The NIACC program has had another Tapco Tools brake for about 20 years that is still going strong. The new brake will allow for the original brake to be used by the program’s regional academies without sacrificing budget.

“I can’t thank you enough,” Helmich says. “It humbles me and gives me an attitude of gratitude to the company to be able to see the value and the importance of skills education.”

The feeling is mutual: “The NIACC Building Trades Diploma Program is doing important work in training the next generation of contractors and preserving the construction craft,” said Adam Clark, Product Manager at Westlake Royal Building Products. “We couldn’t be more thrilled to support their efforts with a new Tapco Tools brake, and we look forward to seeing the students learn and grow in the trades.”